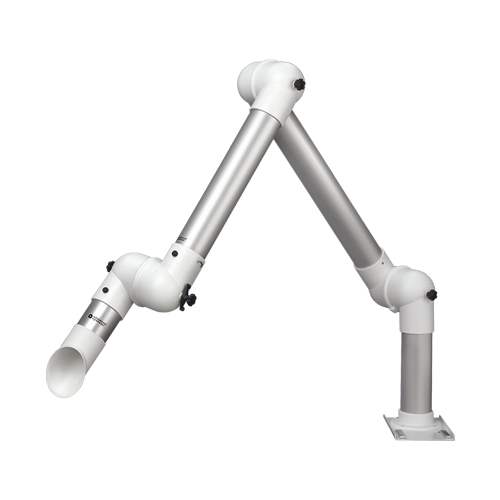

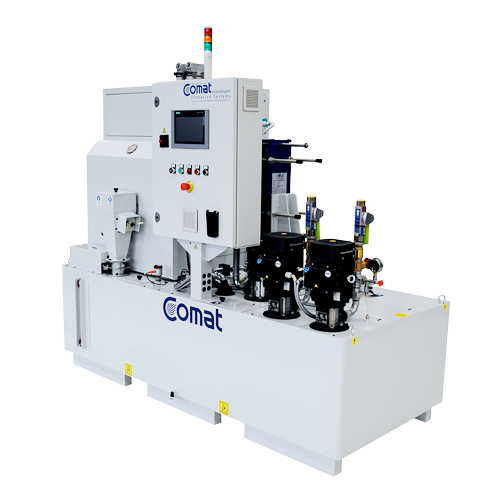

Solutions de filtration

Expert en purification d’air, aspiration et filtration de fluides et particules.

Applications

Vous produisez des poussières, du brouillard d’huile, de la fumée, des odeurs ou d’autres nuisances? Votre huile de coupe est saturée par des particules? Nous avons la bonne solution.

En savoir plus-

3 Millions

Plus de 3 millions d'appareils vendus par ELBARON SA équipent des entreprises réparties dans le monde entier.

-

3000

Plus de 3000 clients fidèles en Suisse et partout dans le monde.

-

40

ELBARON SA s'appuie sur une expérience de plus de 40 ans dans le secteur de la filtration industrielle.

-

Présence mondiale

Nos produits sont représentés par plus de 15 partenaires sur le plan international.